Gaon Group - Quality and Standards

Gaon regards quality to be of the utmost importance and invests heavily in compliance with the quality and safety requirements for pipe compliance with standards and specifications.

The subsidiaries comply with a variety of quality and certification standards, which are awarded by leading accreditation authorities in Israel and worldwide.

Middle East Tube Company

Middle East Tube Company Ltd. has a quality assurance system which is in compliance with the quality requirements and has been certified as compliant with these requirements by the following accreditation authorities:

Compliant with the requirements of the ISO 9001 Standard by Lloyd’s Register Quality Assurance (LRQA).

Compliant with the requirements of the American Petroleum Institute A.P.I.

Compliant with the requirements of the Israeli Standard Seal by the Standards Institute of Israel

All of the welding processes are tested using ultrasonic systems in the production line loop.

All pipes undergo high-pressure resilience and seal testing.

In addition, all of the pipes intended for transmitting fuel and gas undergo an additional ultrasonic test after the pipe has passed the static pressure test. These pipes have a computerized tracking system which documents all of the manufacturing stages and quality tests of each and every pipe.

Hakohav

Through the use of innovative technologies from the metalworking stage through the assembly, oven painting, proprietary coating methods and state-of-the-art test equipment, the company’s customers benefit from comprehensive, reliable solutions suitable for withstanding even the most demanding operating environment.

The proprietary vulcanizing technology, in which the rubber is integrated into the valve body, through controlled application of heat and pressure, enables manufacturing of durable valves, which provide longer lifetimes than is commonly available in the market.

All of Hakohav’s products are manufactured under the supervision of the Israel Standards Institute and are in compliance with the world’s most stringent international standards (NSF, UL, FM, ISO, GOST)

Madey Vered

Madey Vered develops and manufactures high-quality, reliable products. The Madey Vered manufacturing facilities use modern manufacturing processes, which are closely supervised by the Company’s Quality Assurance Department.

The Company is certified to the standards and certifications common to its industry:

Sagiv

Sagiv operates in accordance with the ISO 9001:2015 standard. Quality is integrated in each one of the manufacturing stages. The factory’s production system is based on a set of procedures, which gets updated from time to time and covers each one of the manufacturing steps from raw material quality through to product delivery to the Customer.

The Company’s quality assurance team is equipped with the best technologies and operates in accordance with the stringent MIL Standard in order to retain the reputation for quality the factory has built over time.

Among the standards for which the Factory has been certified:

DIN | BSI | ISI | UL | ISO9001:2015

The Factory operates in accordance with the environmental protection guidelines specified in the appropriate standards.

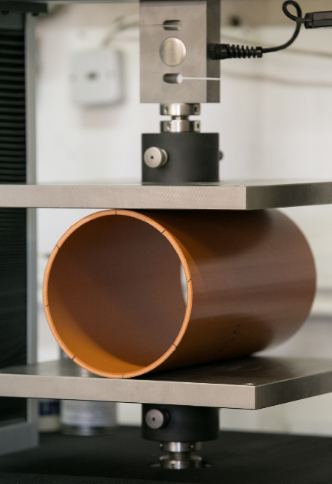

Plassim Palgal

The Plassim-Palgal Factory has an ISO9001:2015-certified Quality Management System. At the same time, the Company’s products are compliant with the relevant accreditations from international standard institutes and almost all products are certified to the Israeli Standard Seal (both the products manufactured at the Plassim Factory and the imported products).

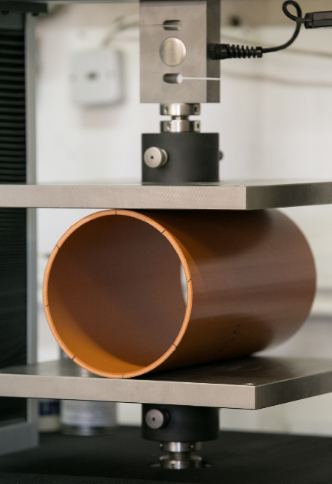

The Plassim-Palgal Factory has an advance quality control laboratory, which applies end-to-end supervision of the entire manufacturing process. This begins with meticulous inspections of the raw materials, through tracking the production lines in action, to pre-delivery quality control.

Testimony to the high quality of the Plassim pipes is, among other things, the fact that almost year after year the company is awarded the highest recognition in the form of the “Perseverance in Pursuing Product Quality” Award, which it receives from the Standards Institute of Israel. The Palgal products are also certified to the following:

Galflex – Standards Institute Permit

PEXline YOW-DS System Standard – Standards Institute Permit

Electricity ducts – Standards Institute Permit

Movilit – Standards Institute Permit

PEXline NTM System Standard – Standards Institute Permit

PEXline NTM System Standard – Standards Institute Permit

FM standard for Galnur-FlameGuard Systems

UL standard for Galnur-FlameGuard Systems