Water Transmission

Sewage Treatment

Fuel and Gas

Industry and Fire Extinguishing

Desalination

AMR/AMI Systems

Support for a wide range of telecommunication platforms

Advanced solutions for industry

The People Make the Difference

Drinking water systems

Gas systems

Air conditioning systems

Fuel and oil systems

Irrigation systems

Caravan products

Household piping

Water infrastructures

Sewerage and drainage

Gas systems

Electricity and Telecommunication

Industry

Fire extinguishing

Plumbing

Agriculture

Household

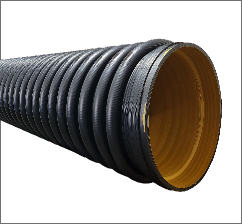

PVC piping for water supply and sewage

PVC-U piping For channelization and underground sewerage

PE100 piping

PE100 piping For water supply under pressure

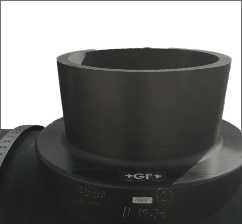

Pipe fittings

Pipe fittings

Merikra piping

Merikra piping For drainage and sewerage

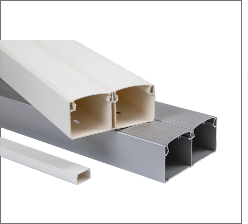

Electricity and telecommunication ducts

Electricity and telecommunication ducts

Jacking pipes

Integrated jacking pipes enable laying steel piping while crossing highways without requiring road closure or traffic interruptions. The integrated solution consists of a concrete pipe, within which a steel pipe is cast. The integrated jacking pipe is then inserted into the ground. This solution combines the advantages of the steel pipe, which is capable of […]

Spherical bell

A steel pipe connected on-site using the bell-and-socket method with spherical bell and socket. This solution enables quick connection of the socket to the bell while enabling slight rotations of up to 6°. The process of connecting is quick, saving the effort needed to match pipe ends and using elbows.

Trio 4

High-Density Polyethylene (HDPE) coating, 4 mm thickness. The wrap features high mechanical strength, good resistance to rocks within the trench and it delivers an excellent solution for pipelaying in difficult terrain conditions. The wrap saves the need for flow concrete.

CANUSA wraps

Heat-shrinking wraps, easily applied, for completing the Trio coating after the pipes have been laid and welded. The wraps, manufactured in Canada by CANUSA, which is one of the world’s leading providers of solutions for laying steel piping, completing the “heads” and the accessories and materials for repairing malfunctions.

14-Meter Piping

Steel pipes come in a standard length of 12.20 Meters. In special projects, if ordered in advance, coated pipes can be provided at lengths of up to 14 Meters. This enables the customer to save on transport costs, laying and welding costs – savings which can amount to up to 14%